|

| June 11, 2013 | Volume 09 Issue 22 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Overhung load adaptors provide load support and contamination protection

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Learn more.

Why choose electric for linear actuators?

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Get this informative e-book. (No registration required)

New AC hypoid inverter-duty gearmotors

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Learn more.

Next-gen warehouse automation: Siemens, Universal Robots, and Zivid partner up

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Read the full article.

Innovative DuoDrive gear and motor unit is UL/CSA certified

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

Learn more.

BLDC flat motor with high output torque and speed reduction

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Learn more and view all the specs.

Application story: Complete gearbox and coupling assembly for actuator system

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Read this informative GAM blog.

Next-gen motor for pump and fan applications

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

Learn more.

Telescoping linear actuators for space-constrained applications

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Learn more.

Competitively priced long-stroke parallel gripper

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

Learn more.

Extend your range of motion: Controllers for mini motors

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

Learn more.

When is a frameless brushless DC motor the right choice?

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

View the video.

Tiny and smart: Step motor with closed-loop control

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Learn more.

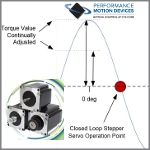

Closed loop steppers drive new motion control applications

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

Read this informative Performance Motion Devices article.

Intelligent compact drives with extended fieldbus options

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

Learn more.

Bye bye hydrazine: Powerful 'green' spacecraft fuel will propel a mission in 2015

By Robert P. White, Air Force Office of Scientific Research

In 2015, NASA, for the first time, will fly a space mission using a radically different propellant -- one that has reduced toxicity and is environmentally benign. This energetic ionic liquid, or EIL, is quite different from the historically employed hydrazine-based propellant, which was first used as a rocket fuel during World War II for the Messerschmitt Me 163B (the first rocket-powered fighter plane).

Within the U.S. space program, hydrazine was used on the 1970s Viking Mars program, and more recently in the Phoenix lander and Curiosity rover Mars missions, as well as in the Space Shuttle's auxiliary power units. Significantly, monopropellant hydrazine-fueled rocket engines are the norm in controlling the terminal descent of spacecraft. What makes hydrazine desirable as a propellant for this terminal descent role is that, when combined with various catalysts, the result is an extremely exothermic reaction that releases significant heat in a very short time, producing energy in the form of large volumes of hot gas from a relatively small volume of hydrazine liquid.

Unfortunately, hydrazine has several significant drawbacks: It is very toxic when inhaled, corrosive on contact with skin, hazardously flammable, and falls short in providing the propulsive power required for future spacecraft systems. In 1998, driven by these challenges, Dr. Michael Berman, a program manager at the Arlington, Va.-based Air Force Office of Scientific Research (AFOSR), the basic research arm of the Air Force Research Laboratory (AFRL), funded Dr. Tom Hawkins of the Propellants Branch, Rocket Propulsion Division at AFRL's Aerospace Systems Directorate, to find a more benign, yet even more powerful material to replace hydrazine.

This research effort was ultimately associated with a joint government and industry development program, the Integrated High Payoff Rocket Propulsion Technology (IHPRPT) initiative, to improve U.S. rocket propulsion systems. IHPRPT challenged the Department of Defense, the National Air and Space Administration, and the rocket propulsion industry to double U.S. rocket propulsion capability (cost and performance) by 2010. Beginning in 1996, this IHPRPT challenge meant the development of propellants that would provide far greater energy density than current state-of-the-art propellants.

Hawkins' interest in EILs began early on in his career beginning at Lehigh University when he worked on advanced propellants for the Strategic Defense Initiative in the 1980s. Knowing the untapped potential of ionic liquids to provide high-energy-density materials, he embarked on an effort to design and characterize the EIL family. This effort was funded by AFOSR and continues to the present day.

"We were on the right track [in 2002] when we produced an ionic liquid monopropellant that incorporated an EIL that was investigated under our AFOSR program," said Hawkins. "This propellant class, known as AF-M315, has an energy density close to twice that of the state-of-the-art spacecraft monopropellant, hydrazine."

With additional support from the IHPRPT program, the Missile Defense Agency (MDA), and related USAF missile programs, a full characterization of one of these new propellants, AF-M315E, was investigated for its overall safety and hazard properties. According to Hawkins, these safety properties, coupled with the performance of AF-M315E, were "... absolutely outstanding; we found the oral toxicity of AF-M315E to be less than that of caffeine, and its vapor toxicity to be negligible. The vapor flammability of AF-M315E was essentially nil, and this made it difficult to unexpectedly ignite and sustain combustion of AF-M315E -- one could even put out small fires with the propellant!"

Combustion using AF-M315E does require a higher temperature, though, compared to hydrazine.

In 2005, NASA took a keen interest in this very promising alternative to hydrazine and performed further evaluations. Follow-on work performed by Aerojet, Inc. brought AF-M315E engine design to a level that was very attractive for a technology transition to the commercial sector. But for that to occur, it was necessary to find a champion to sponsor the flight demonstration that would make AF-M315E spacecraft propulsion an "off-the-shelf" choice for future propulsion systems. NASA became that champion in 2012 with their selection of Ball Aerospace & Technologies Corporation as the lead integrator for the Green Propellant Infusion Mission -- a $45 million program that will produce new AF-M315E-based thrusters for NASA's 2015 spacecraft mission. Additional program team members consist of the AFRL, Aerojet, the Air Force Space & Missile Systems Center, and the NASA/Glenn Research Center.

The field of energetic ionic liquids is the product of AFOSR-sponsored research at AFRL that is changing the landscape of work in the energetic materials community.

"The AFOSR-funded program provided the synthesis and characterization work for an EIL that enabled the experimental USAF fuel, AF-M315E, to act as a high-energy-density, environmentally benign, easy-to-handle replacement for spacecraft hydrazine fuel," said Hawkins.

Hawkins also noted that 20 years is a well-recognized time period for producing such a revolutionary propellant approach and propulsion system due to the fact that the EIL approach to liquid propulsion is completely different than that of hydrazine, and, most significantly, the performance potentials of EIL-based propellants are not small incremental improvements, but significantly larger than any state-of-the-art propellant. As EIL-based propellants are developed, they will provide lower-cost and safer propulsion system operations along with greater mission flexibility and faster mission response times.

Published May 2013

Rate this article

View our terms of use and privacy policy